Good or Bad roll?

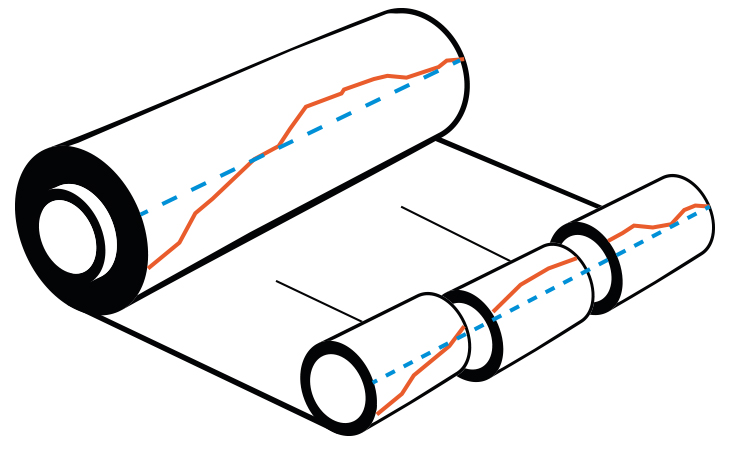

The end product of a roll manufacturing process is the customer roll. Even if the roll is cut, sheeted, rewound or alternatively finished, it must form a good roll prior converting. The costs associated with bad rolls is manifold. The bad roll can cause a claim towards roll supplier, it may slow down the converting process due to altering machine set ups or eventually it may cause troubles in the end use.

We at ACA Systems are securing your competitive edge by providing advanced and clever analyzers to provide answer to simple question: good or bad roll?

Good or bad roll based on sophisticated roll hardness profile data

Roll hardness is probably the most important factor in determining the difference between a good and bad roll. Rolls that are wound too soft will go out of round or telescoping while winding, handled or stored. Rolls that are wound too tight will contain high inwound tension. Such rolls due to bad handling, when dropped or squeezed hard by a roll handling truck can have major internal web burst etc.

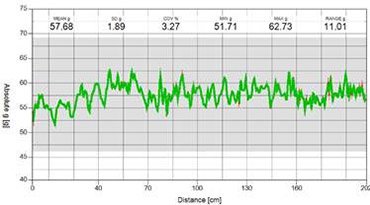

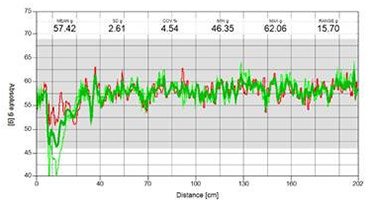

However, the great majority of roll problems are related to uneven hardness profile of the roll in CD direction. A poor hardness profile can indicate issues such as loose edges, bagginess, rope marks etc… It has been suggested that if the variation in reel hardness (COV %) is less than 3.5%, the roll is considered to be relatively good.

In contrast, if the hardness variation is approximately greater than 6.0%, then there is a high possibility that the roll is bad and can cause unnecessary costs in some part of the value chain. Perhaps the roll needs to be eliminated?

Good roll (CoV 3.3 %)

Bad roll (CoV 4,5%), probably issues with loose edge

Related case studies

Good or bad porous rolls based on real-time air permeability measurement

Porosity or air permeance is a key property of materials such as filter media, battery separator films, breathable films and many other technical roll products.

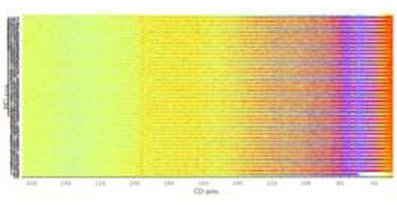

Very often the customer applications can be very small compared to production size jumbo rolls, therefore the consistency of a roll material is very important. Laboratory analysis often take into account only few points of the roll, assuming the whole roll is uniform.

In contrast an online measurement takes up to 15 000 data points from one roll and draws a color map in CD and MD direction, basically describing the uniformity from each roll produced.

Bad roll (non-uniform permeability)

Related case studies: